Calhoun, Ga.— Durkan has launched an all-new precision dye injection (PDI) carpet tile program featuring the technology that initially debuted with broadloom for hospitality interiors.

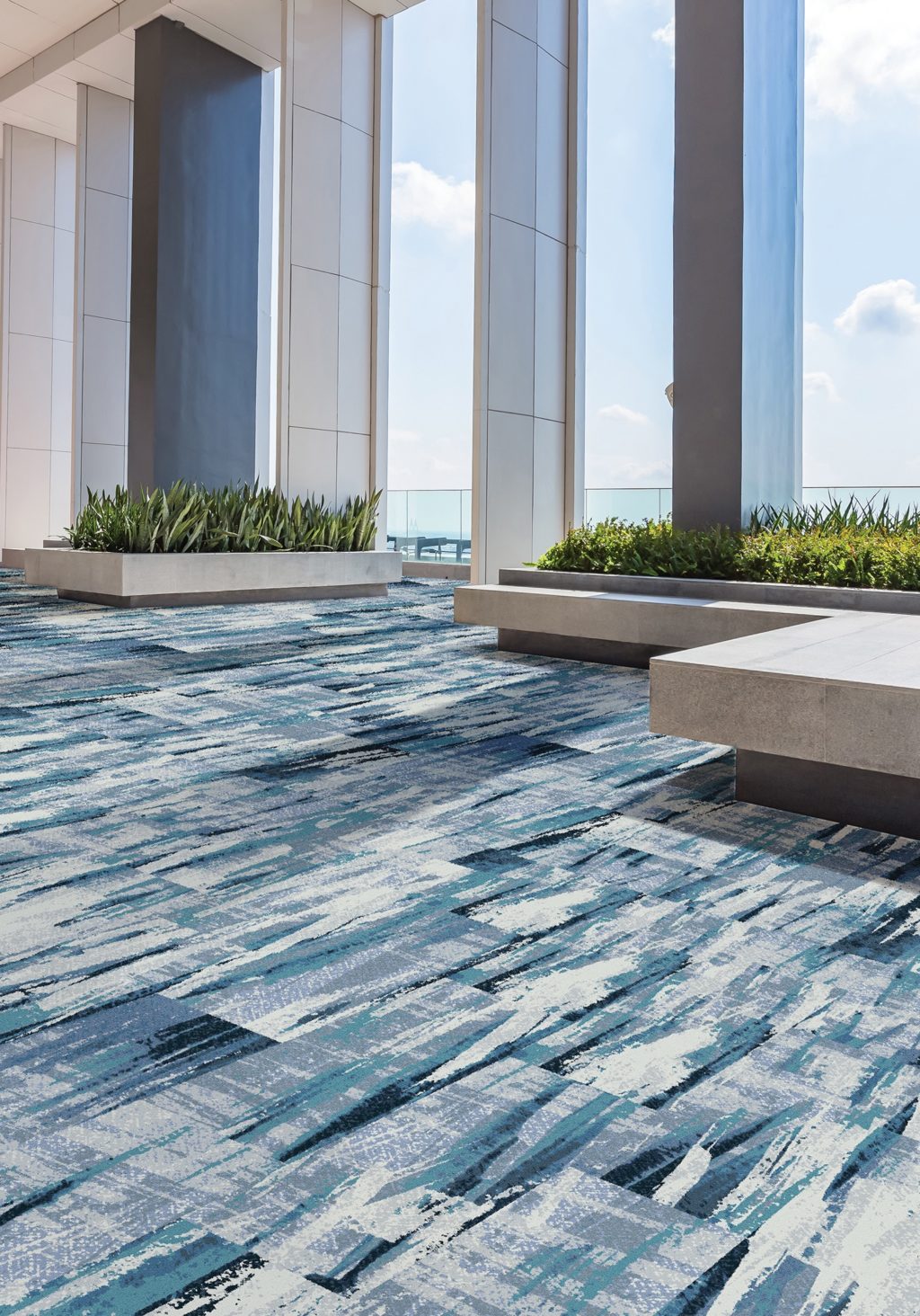

PDI tile allows designers to create enduring pattern combinations with easy-to-install formats, all while increasing longevity through replacement of individually damaged tiles instead of the entire floor. Synthesis, Durkan’s patented carpet technology, brings the innovative PDI styles to life. The proprietary process layers pattern and texture to provide 3D image quality and clarity. The result is a unique layering effect that brings tremendous depth and richness to carpet design.

Transpositions is the first collection launched under the program. The collection is inspired by mathematical concepts, and transforms any hospitality space into an interchangeable design landscape to provide one-of-a-kind experiences for hospitality guests, according to Durkan.

“From product development to manufacturing, our team worked closely to curate this innovative, customer-centered carpet tile program through thoughtful selection of its yarn types, designs, sizing, textures and backings,” said Seth Brewer, director of product management for Durkan. “Our PDI tile program is modeled around a simple ordering process, quick delivery, the lowest upfront costs and the lowest cost of ownership to generate the most beautiful, high-performing flooring in the industry for our valued hospitality customers.”

Running line PDI tile bases include Shaka (20-ounce), Beach Breaker (36-ounce) and Second Wave (36-ounce). All three options are available with a five-week lead time and a low minimum order quantity of 133 square yards. Custom bases also include any of Durkan’s current broadloom Synthesis bases, which can be converted into tile, such as Ripple, Stria and Downstream. Custom bases are available with a 10-week lead time and 1,500-square-yard minimum order.

All styles within the program are manufactured using ColorStrand nylon fiber, which features unsurpassed colorfastness to light, atmospheric contaminants and harsh cleaning agents, delivering both lasting beauty and value, the company said. All PDI tiles come standard on EcoFlex NXT AIR backing, which features an attached cushion that offers substantial sound reduction and enhanced comfort underfoot.